In recent years, the manufacturing sector has witnessed a troubling surge in the theft of CNC (Computer Numerical Control) machine tools. These sophisticated machines, integral to modern production processes, have become prime targets for thieves due to their high value and demand in various industries. The rise in CNC machine tool theft can be attributed to several factors, including the increasing sophistication of criminal networks and the growing reliance on these tools in manufacturing.

As industries strive for efficiency and precision, the allure of stealing such equipment has only intensified, leading to a concerning trend that poses significant challenges for manufacturers. The theft of CNC machines is not merely a localized issue; it has become a widespread phenomenon affecting businesses across the globe. Criminals have adapted to the technological advancements in manufacturing, often employing organized tactics to execute their heists.

Reports indicate that these thefts are not just opportunistic; they are often planned with meticulous detail, involving insider knowledge and advanced logistics. As a result, manufacturers are left grappling with the repercussions of these thefts, which can lead to substantial financial losses and disruptions in production schedules.

Key Takeaways

- CNC machine tool theft is on the rise, posing a significant threat to manufacturing industries worldwide.

- The impact of CNC machine tool theft extends beyond financial losses, affecting production, reputation, and customer trust.

- Security measures for CNC machine tools have evolved to include advanced technologies such as GPS tracking and remote monitoring.

- CNC machine tool theft has a global reach, with stolen equipment often being sold in international black markets.

- Technology plays a crucial role in combatting theft, with advancements in tracking and authentication systems improving security measures.

The Impact on Manufacturing Industries

The ramifications of CNC machine tool theft extend far beyond the immediate loss of equipment. For many manufacturing industries, these machines are the backbone of their operations, enabling them to produce high-quality products efficiently. When a CNC machine is stolen, it can halt production lines, delay project timelines, and ultimately affect a company’s bottom line.

The ripple effects can be felt throughout the supply chain, as delays in production can lead to missed deadlines and dissatisfied customers. Moreover, the impact of such thefts can also be seen in the broader economic landscape. Industries that rely heavily on CNC machining, such as aerospace, automotive, and electronics, may experience increased costs as they scramble to replace stolen equipment or invest in additional security measures.

This not only affects individual companies but can also lead to higher prices for consumers as manufacturers pass on the costs associated with theft and recovery efforts. The overall competitiveness of these industries may be compromised as they struggle to maintain efficiency in the face of such challenges.

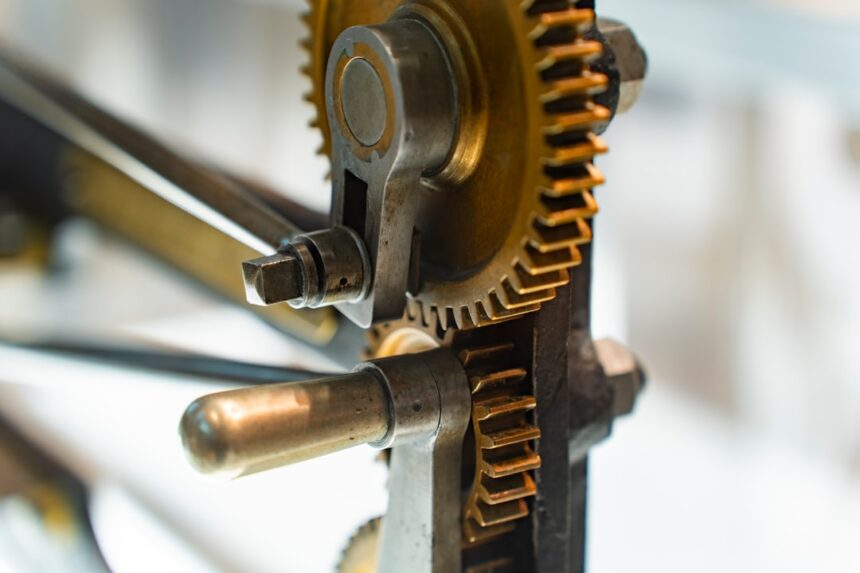

The Evolution of CNC Machine Tool Security Measures

In response to the rising threat of CNC machine tool theft, manufacturers have begun to implement a variety of security measures aimed at safeguarding their assets. Initially, security protocols were relatively basic, often relying on physical locks and surveillance cameras. However, as thefts became more sophisticated, so too did the security solutions employed by manufacturers.

Today, many companies are investing in advanced technologies such as biometric access controls, GPS tracking systems, and integrated alarm systems that provide real-time alerts in the event of unauthorized access. Furthermore, the evolution of security measures has also led to a greater emphasis on employee training and awareness. Companies are recognizing that human error can often be a significant factor in security breaches.

By educating employees about the importance of safeguarding equipment and recognizing suspicious behavior, manufacturers can create a culture of vigilance that helps deter potential thieves. This multifaceted approach to security not only protects valuable assets but also fosters a sense of responsibility among employees.

The Global Reach of CNC Machine Tool Theft

| Country | Number of CNC Machine Tool Thefts |

|---|---|

| United States | 127 |

| Germany | 89 |

| Italy | 73 |

| Japan | 56 |

| China | 42 |

CNC machine tool theft is not confined to any single region; it is a global issue that transcends borders. Criminal organizations have recognized the lucrative nature of these machines and have expanded their operations internationally. Reports indicate that stolen CNC machines are often trafficked across countries, making it challenging for law enforcement agencies to track and recover them.

This global reach complicates efforts to combat theft and necessitates international cooperation among law enforcement agencies. The interconnectedness of the global economy further exacerbates the problem. As manufacturers source components and machinery from various countries, the risk of theft increases.

Stolen CNC machines may end up in markets far removed from their original locations, making recovery efforts even more difficult. This international dimension highlights the need for a coordinated response to CNC machine tool theft that involves collaboration between governments, law enforcement agencies, and industry stakeholders.

The Role of Technology in Combatting Theft

Technology plays a pivotal role in both facilitating CNC machine tool theft and combatting it. On one hand, advancements in technology have made it easier for criminals to execute sophisticated heists. For instance, thieves may use drones or other surveillance tools to gather intelligence on manufacturing facilities before carrying out their plans.

Additionally, the rise of online marketplaces has created new avenues for selling stolen equipment, further complicating recovery efforts. On the other hand, technology also offers innovative solutions for preventing theft. Manufacturers are increasingly turning to smart technologies that integrate with their CNC machines to enhance security.

For example, IoT (Internet of Things) devices can monitor machine usage and alert owners to any unusual activity. Furthermore, blockchain technology is being explored as a means of creating secure records of ownership and transactions related to CNC machines, making it more difficult for stolen equipment to be sold without detection.

The Economic Consequences of CNC Machine Tool Theft

The economic consequences of CNC machine tool theft are profound and multifaceted. For individual manufacturers, the immediate financial impact can be staggering. The cost of replacing stolen equipment can run into hundreds of thousands or even millions of dollars, depending on the scale of operations.

Additionally, companies may face increased insurance premiums as they seek coverage for their assets in light of rising theft rates. Beyond individual companies, the broader economic implications are equally concerning. As manufacturers grapple with the fallout from thefts, productivity may decline, leading to reduced output and potential job losses within affected industries.

The cumulative effect can stifle innovation and growth within sectors that rely heavily on CNC machining technology. Furthermore, as companies invest more resources into security measures rather than research and development or workforce training, the long-term competitiveness of entire industries may be jeopardized.

The Connection to International Espionage

CNC machine tool theft is not merely a crime driven by financial gain; it is also intricately linked to international espionage activities. In an era where technological advancements are paramount for economic success, stealing advanced manufacturing equipment can provide significant advantages to rival nations or corporations. Reports have surfaced indicating that some thefts are orchestrated by state-sponsored actors seeking to acquire cutting-edge technology without incurring the costs associated with research and development.

This connection between theft and espionage raises serious concerns about national security and economic stability. As countries vie for technological supremacy, the stakes associated with CNC machine tool theft become even higher. Governments must remain vigilant in addressing this issue, recognizing that protecting intellectual property and manufacturing capabilities is essential for maintaining competitive advantages on the global stage.

The Importance of Collaboration in Fighting Theft

Addressing the issue of CNC machine tool theft requires a collaborative approach that involves multiple stakeholders. Manufacturers must work closely with law enforcement agencies to share information about theft trends and tactics employed by criminals. By fostering open lines of communication, companies can help law enforcement develop targeted strategies for preventing and investigating thefts.

Additionally, collaboration extends beyond national borders. International partnerships between governments and industry organizations can facilitate information sharing and best practices for combating CNC machine tool theft on a global scale. By pooling resources and expertise, stakeholders can develop comprehensive strategies that address both prevention and recovery efforts.

The Future of CNC Machine Tool Security

As technology continues to evolve, so too will the landscape of CNC machine tool security. Manufacturers will need to stay ahead of emerging threats by adopting innovative security solutions that leverage advancements in artificial intelligence, machine learning, and data analytics. Predictive analytics could play a crucial role in identifying potential vulnerabilities before they are exploited by criminals.

Moreover, as cyber threats become increasingly prevalent, manufacturers must also consider cybersecurity measures alongside physical security protocols. Protecting sensitive data related to CNC machines will be essential in preventing unauthorized access and ensuring that proprietary information remains secure.

The Human Cost of CNC Machine Tool Theft

While much attention is often focused on the financial implications of CNC machine tool theft, it is essential not to overlook the human cost associated with these crimes.

The loss of equipment can lead to job insecurity and reduced morale among workers who take pride in their contributions to production processes.

Furthermore, communities that rely on manufacturing jobs may suffer when companies face financial strain due to theft-related losses. Job cuts or facility closures can have devastating effects on local economies, leading to increased unemployment rates and diminished quality of life for residents.

The Ethical and Legal Implications of Theft

CNC machine tool theft raises significant ethical and legal questions that extend beyond individual cases of criminal activity. The act of stealing advanced manufacturing equipment not only violates property rights but also undermines trust within industries that rely on collaboration and innovation. Companies invest substantial resources into developing proprietary technologies; when these assets are stolen, it represents a breach of ethical conduct that can have far-reaching consequences.

Legally, addressing CNC machine tool theft presents challenges for law enforcement agencies tasked with investigating these crimes across jurisdictions.

As manufacturers continue to face this growing threat, it is imperative for lawmakers to consider how existing legal frameworks can be adapted to better address the complexities associated with CNC machine tool theft.

In conclusion, CNC machine tool theft represents a multifaceted challenge that impacts manufacturing industries on numerous levels—from economic consequences to ethical considerations. As technology evolves and criminal tactics become more sophisticated, manufacturers must remain vigilant in their efforts to protect their assets while fostering collaboration among stakeholders to combat this pervasive issue effectively.

In the intricate web of espionage and industrial theft during the Cold War, the theft of CNC machine tools stands out as a significant event that underscored the technological arms race between superpowers. An article that delves into the broader implications of such technological thefts during this tense period can be found on the War Room website. This piece provides a comprehensive analysis of how these clandestine activities influenced global power dynamics and technological advancements. For a deeper understanding of the context and impact of CNC machine tool theft during the Cold War, you can read more in this related article.

WATCH THIS 🤯How the KGB Stole America’s Future

FAQs

What is CNC machine tool theft Cold War?

CNC machine tool theft Cold War refers to the ongoing issue of theft and espionage related to CNC (Computer Numerical Control) machine tools, particularly between major global powers such as the United States, China, and Russia.

Why are CNC machine tools targeted for theft?

CNC machine tools are targeted for theft due to their advanced technology and the potential for reverse engineering and intellectual property theft. These machines are used in the manufacturing of critical components for various industries, making them a valuable target for espionage.

What are the implications of CNC machine tool theft Cold War?

The implications of CNC machine tool theft Cold War include potential economic and national security risks. Stolen technology can be used to undermine the competitiveness of industries and compromise national security by obtaining sensitive manufacturing capabilities.

How are governments and industries addressing CNC machine tool theft?

Governments and industries are addressing CNC machine tool theft through increased cybersecurity measures, export controls, and international cooperation to prevent the illicit transfer of technology. Additionally, companies are implementing stricter supply chain security and monitoring to protect their intellectual property.

What are some notable cases of CNC machine tool theft Cold War?

Notable cases of CNC machine tool theft Cold War include instances of espionage and intellectual property theft involving major global powers. These cases often involve sophisticated cyberattacks, insider threats, and illicit technology transfers aimed at acquiring advanced manufacturing capabilities.