Thermosiphon systems represent a fascinating intersection of thermodynamics and engineering, particularly in their application to environments characterized by extreme temperatures. These systems utilize the natural convection of fluids to transfer heat, relying on the principles of buoyancy and thermal expansion. In essence, a thermosiphon operates without the need for mechanical pumps, making it an energy-efficient solution for heat transfer.

This passive system is particularly advantageous in remote or off-grid locations, where traditional heating methods may be impractical or too costly. In the context of Arctic permafrost, thermosiphon systems have gained prominence as a viable solution for managing ground temperatures and preventing the thawing of permafrost.

The ability of thermosiphons to maintain lower ground temperatures can help mitigate these risks, making them an essential tool for infrastructure development in these sensitive areas. Understanding the unique characteristics of both thermosiphon systems and Arctic permafrost is crucial for engineers and environmental scientists alike.

Key Takeaways

- Thermosiphon systems are crucial for managing heat in Arctic permafrost environments to prevent ground thawing.

- Engineering in Arctic permafrost faces unique challenges such as extreme cold, ground instability, and material durability.

- Proper design and material selection are essential to ensure the efficiency and longevity of thermosiphon systems in harsh permafrost conditions.

- Regular installation and maintenance practices are vital to maintain thermal performance and system reliability over time.

- Innovations and case studies highlight sustainable approaches and future improvements for thermosiphon technology in Arctic permafrost engineering.

Understanding Arctic Permafrost

Arctic permafrost is defined as a layer of permanently frozen soil that exists beneath the surface in polar regions.

The permafrost layer can vary in thickness, ranging from a few meters to over a thousand meters in some areas.

It plays a critical role in the Arctic ecosystem, influencing hydrology, vegetation, and even local wildlife. However, as global temperatures rise, permafrost is beginning to thaw, leading to a host of environmental concerns. The thawing of permafrost can release significant amounts of greenhouse gases, such as methane and carbon dioxide, which have been trapped in the frozen soil for millennia.

This release exacerbates climate change, creating a feedback loop that further accelerates warming. Additionally, the destabilization of permafrost can lead to ground subsidence and erosion, posing risks to infrastructure and communities in these regions. Understanding the dynamics of Arctic permafrost is essential for developing effective engineering solutions that can withstand these changes while minimizing environmental impact.

Challenges of Engineering in Arctic Permafrost

Engineering in Arctic permafrost presents a unique set of challenges that require innovative solutions and careful planning. One of the primary concerns is the potential for ground instability due to thawing permafrost. As the ground warms, it can lead to uneven settling and shifting, which can compromise the integrity of structures built on or within it.

This necessitates a thorough understanding of soil mechanics and geotechnical engineering principles to ensure that foundations are designed to accommodate these changes. Moreover, the extreme cold temperatures prevalent in Arctic regions pose additional challenges for construction and maintenance activities. Equipment may become less reliable in frigid conditions, and materials can behave differently than they would in milder climates.

Engineers must consider these factors when designing structures and systems intended for use in permafrost areas. The need for specialized training and equipment can also increase project costs and timelines, making it imperative for engineers to develop efficient strategies for overcoming these obstacles.

Design Considerations for Thermosiphon Systems

When designing thermosiphon systems for use in Arctic permafrost, several key considerations must be taken into account. First and foremost is the thermal performance of the system. Engineers must ensure that the thermosiphon can effectively transfer heat away from the ground to maintain stable temperatures within the permafrost layer.

This involves careful calculations regarding fluid properties, heat exchange surfaces, and system orientation to optimize natural convection. Another critical design consideration is the integration of the thermosiphon system with existing infrastructure. In many cases, these systems are retrofitted into pre-existing structures or landscapes, necessitating a thoughtful approach to installation that minimizes disruption while maximizing efficiency.

Additionally, engineers must consider potential environmental impacts during the design phase, ensuring that the system does not adversely affect local ecosystems or contribute to further permafrost degradation.

Material Selection for Arctic Permafrost Conditions

| Parameter | Value | Unit | Description |

|---|---|---|---|

| Thermosiphon Length | 3.5 | m | Typical length of thermosiphon pipe installed in permafrost |

| Heat Transfer Rate | 150 | W/m | Heat removal capacity per meter of thermosiphon |

| Operating Temperature Range | -40 to 10 | °C | Temperature range in which thermosiphon effectively operates |

| Permafrost Temperature | -5 to -15 | °C | Typical temperature range of permafrost in Arctic engineering sites |

| Ground Ice Content | 20-40 | % | Volumetric ice content in permafrost soil |

| Thermosiphon Working Fluid | Ammonia | N/A | Common refrigerant used in thermosiphons for permafrost cooling |

| Installation Depth | 2.5 – 4.0 | m | Depth at which thermosiphons are typically installed to stabilize permafrost |

| Cooling Capacity | 500 – 1000 | W | Overall cooling capacity of a single thermosiphon unit |

| Annual Energy Savings | 30 – 50 | % | Energy savings compared to active cooling systems in Arctic conditions |

| Typical Lifespan | 20 – 30 | years | Expected operational lifespan of thermosiphon installations in permafrost |

The selection of materials for thermosiphon systems operating in Arctic permafrost is paramount to their long-term success and durability. Materials must be able to withstand extreme cold temperatures without becoming brittle or losing structural integrity. Common choices include high-grade stainless steel and specialized polymers that offer resistance to both low temperatures and corrosion from moisture.

Furthermore, insulation materials play a crucial role in maintaining thermal efficiency within thermosiphon systems. Engineers must select insulation that can effectively minimize heat loss while remaining functional in freezing conditions. The choice of materials not only affects the performance of the thermosiphon but also its lifespan and maintenance requirements, making it essential for engineers to conduct thorough material assessments before implementation.

Installation and Maintenance of Thermosiphon Systems in Permafrost

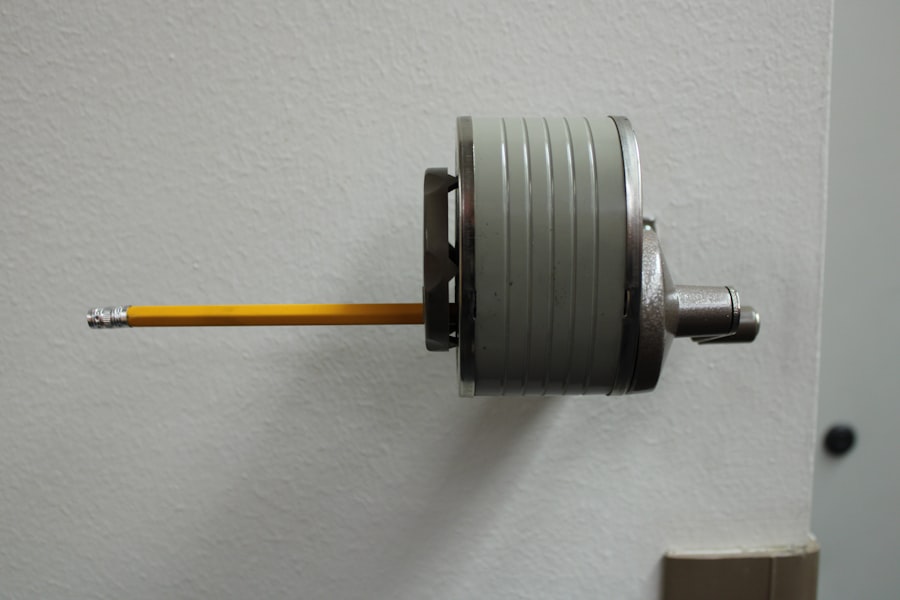

The installation of thermosiphon systems in Arctic permafrost requires meticulous planning and execution to ensure optimal performance. Engineers must assess site conditions thoroughly before installation begins, taking into account factors such as soil composition, moisture levels, and existing infrastructure. The installation process often involves drilling into the permafrost layer to place thermosiphon pipes at appropriate depths where they can effectively transfer heat.

Once installed, regular maintenance is essential to ensure that thermosiphon systems continue to function efficiently over time. This includes monitoring fluid levels, checking for leaks or blockages, and assessing the overall condition of the system components. Given the remote nature of many Arctic locations, maintenance schedules must be carefully planned to minimize disruptions while ensuring that systems remain operational throughout their lifespan.

Thermal Performance and Efficiency of Thermosiphon Systems in Arctic Permafrost

The thermal performance and efficiency of thermosiphon systems in Arctic permafrost are critical metrics that determine their effectiveness in managing ground temperatures. Engineers utilize various modeling techniques to predict how well a thermosiphon will perform under specific conditions, taking into account factors such as ambient temperature fluctuations and soil thermal properties. These models help inform design decisions and optimize system configurations for maximum efficiency.

In practice, successful thermosiphon systems have demonstrated impressive thermal performance in maintaining stable ground temperatures even as external conditions fluctuate dramatically. By leveraging natural convection processes, these systems can effectively transfer heat away from sensitive areas, thereby reducing the risk of permafrost thawing and its associated consequences. Continuous monitoring and data collection are essential for evaluating system performance over time and making necessary adjustments to enhance efficiency.

Environmental Impact and Sustainability of Thermosiphon Systems in Permafrost

The environmental impact of thermosiphon systems in Arctic permafrost is an important consideration for engineers and policymakers alike. While these systems offer a means of mitigating permafrost thawing, their installation and operation must be conducted with sustainability in mind. This includes minimizing disturbances to local ecosystems during installation and ensuring that materials used are environmentally friendly.

Moreover, engineers must consider the long-term implications of thermosiphon systems on local wildlife and vegetation. By carefully assessing potential impacts and implementing best practices for installation and maintenance, it is possible to strike a balance between infrastructure development and environmental stewardship. The goal should be to create solutions that not only address immediate engineering challenges but also contribute positively to the overall health of Arctic ecosystems.

Case Studies of Successful Thermosiphon Systems in Arctic Permafrost

Numerous case studies highlight the successful implementation of thermosiphon systems in Arctic permafrost regions. One notable example is found in Alaska, where engineers installed a network of thermosiphons beneath critical infrastructure such as roads and buildings. These systems have proven effective in maintaining stable ground temperatures, thereby preventing damage from thawing permafrost.

Another case study from Canada showcases how thermosiphons were integrated into a research facility located on permafrost terrain. The facility’s design included multiple thermosiphons strategically placed to manage heat transfer effectively while minimizing environmental impact. The success of these installations has provided valuable insights into best practices for future projects in similar conditions.

Future Developments and Innovations in Thermosiphon Systems for Permafrost

As climate change continues to pose challenges for Arctic regions, ongoing research and innovation in thermosiphon systems are essential for improving their effectiveness and sustainability. Future developments may include advancements in materials science that lead to more efficient heat transfer fluids or enhanced insulation technologies that further reduce energy loss. Additionally, integrating smart technology into thermosiphon systems could revolutionize their operation by allowing real-time monitoring and automated adjustments based on environmental conditions.

Such innovations would not only enhance system performance but also contribute to more sustainable engineering practices in sensitive Arctic environments.

Conclusion and Recommendations for Engineering Thermosiphon Systems in Arctic Permafrost

In conclusion, thermosiphon systems offer a promising solution for addressing the challenges posed by thawing Arctic permafrost. Their ability to passively manage ground temperatures makes them an attractive option for infrastructure development in these sensitive regions. However, successful implementation requires careful consideration of design parameters, material selection, installation practices, and ongoing maintenance.

Engineers are encouraged to adopt a holistic approach that prioritizes sustainability while addressing immediate engineering needs. By learning from past case studies and embracing innovative technologies, it is possible to create resilient solutions that protect both infrastructure and the fragile Arctic environment for generations to come.

In the context of thermosiphon permafrost engineering in the Arctic, understanding the challenges and solutions related to ground temperature management is crucial. A related article that delves into these issues can be found at In the War Room, where it discusses innovative approaches to maintaining the stability of infrastructure in permafrost regions. This resource provides valuable insights into the engineering techniques that can mitigate the effects of climate change on Arctic environments.

WATCH THIS! 🎬 America’s Nuclear City Was a Lie: The Russian Base That Made Iceworm Obsolete

FAQs

What is a thermosiphon in permafrost engineering?

A thermosiphon is a passive heat exchange device used in permafrost engineering to transfer heat from the ground to the air, helping to maintain or lower the temperature of the permafrost and prevent thawing beneath structures.

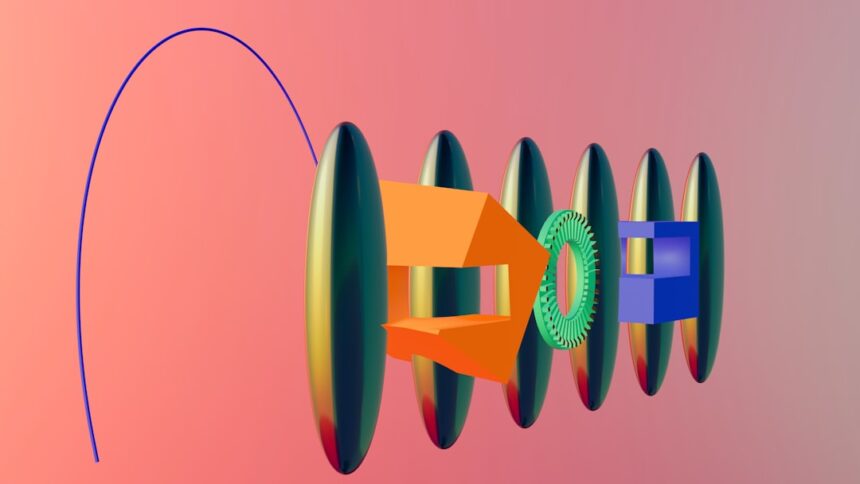

How does a thermosiphon work in Arctic conditions?

In Arctic conditions, a thermosiphon uses the natural convection of a working fluid that evaporates at the warm ground interface and condenses in the colder air above, transferring heat away from the soil without the need for external power.

Why is thermosiphon technology important for permafrost engineering?

Thermosiphons help stabilize permafrost by preventing thawing caused by heat from buildings or infrastructure, thereby reducing ground settlement and structural damage in Arctic environments.

What types of structures benefit from thermosiphon installation?

Buildings, pipelines, roads, and other infrastructure built on or near permafrost benefit from thermosiphons to maintain ground stability and extend the lifespan of the structures.

Are thermosiphons environmentally friendly?

Yes, thermosiphons are environmentally friendly because they operate passively without electricity or fuel, relying solely on natural temperature differences to function.

What are the main components of a thermosiphon system?

A typical thermosiphon consists of a sealed pipe or tube filled with a working fluid, a ground heat exchanger section, and an air-cooled condenser section exposed to the cold Arctic air.

Can thermosiphons be used in all permafrost regions?

Thermosiphons are most effective in regions with cold winters and permafrost near the surface. Their efficiency depends on local climate conditions, soil properties, and the design of the system.

How long do thermosiphons typically last?

Thermosiphons are designed for long-term use, often lasting several decades with minimal maintenance, making them suitable for permanent infrastructure in permafrost areas.

What challenges are associated with using thermosiphons in Arctic engineering?

Challenges include ensuring proper installation, selecting appropriate working fluids, dealing with extreme weather conditions, and adapting designs to varying permafrost and soil characteristics.

Are there alternatives to thermosiphons for permafrost protection?

Alternatives include active cooling systems, insulation layers, adjustable foundations, and other ground stabilization techniques, but thermosiphons are preferred for their passive operation and reliability.