The timeline for cable repair is a critical aspect that influences the overall efficiency and effectiveness of the repair process. Understanding this timeline involves recognizing the various stages that must be navigated, from the initial assessment of damage to the final restoration of service. Each phase has its own set of challenges and time requirements, which can vary significantly based on the extent of the damage, the type of cable involved, and environmental factors.

A well-structured timeline not only helps in managing resources effectively but also sets realistic expectations for stakeholders. In many cases, the timeline begins with an immediate response to a reported issue, followed by a thorough evaluation of the damage. This initial assessment is crucial as it determines the scope of work required and informs subsequent planning.

Depending on the complexity of the situation, this phase can take anywhere from a few hours to several days. Once the assessment is complete, a detailed repair plan is developed, which includes scheduling, resource allocation, and risk management strategies. This structured approach ensures that all parties involved are aligned and prepared for the tasks ahead.

Key Takeaways

- Effective cable repair requires thorough assessment and careful planning before starting the work.

- Securing permits and coordinating with utility companies are critical steps to avoid delays.

- Safety protocols must be strictly implemented to protect repair crews during the operation.

- Continuous communication with stakeholders ensures transparency and manages expectations.

- Monitoring progress and documenting the process help ensure quality and facilitate future repairs.

Assessing the Damage and Planning for Repair

Assessing the damage is a pivotal step in the cable repair process, as it lays the groundwork for effective planning. Technicians and engineers typically conduct a comprehensive evaluation to identify not only the visible damage but also any underlying issues that may not be immediately apparent. This assessment often involves using specialized equipment to test cable integrity and functionality.

The findings from this evaluation guide the decision-making process regarding repair methods and materials needed. Once the assessment is complete, planning for repair can commence. This phase involves creating a detailed action plan that outlines each step of the repair process, including timelines, required personnel, and equipment.

It is essential to consider potential challenges that may arise during repairs, such as adverse weather conditions or unexpected complications related to existing infrastructure. By anticipating these issues, teams can develop contingency plans that minimize delays and ensure a smoother repair process.

Securing Necessary Permits and Permissions

Before any physical work can begin, securing the necessary permits and permissions is a crucial step in the cable repair process. This often involves navigating a complex web of regulations and requirements set forth by local authorities and utility companies. Depending on the location and nature of the repair, various permits may be required to ensure compliance with safety standards and environmental regulations.

The process can be time-consuming, but it is essential for avoiding legal complications down the line. In addition to obtaining permits, it is also important to communicate with relevant stakeholders about the planned repairs. This includes informing local residents, businesses, and other affected parties about potential disruptions or changes in service.

By fostering open lines of communication, repair teams can build trust within the community and mitigate any concerns that may arise during the repair process. This proactive approach not only helps in securing necessary permissions but also enhances overall project transparency.

Sourcing and Procuring Materials and Equipment

Once permits are secured, the next step involves sourcing and procuring the materials and equipment necessary for the repair. This phase requires careful consideration of quality, cost, and availability. Depending on the nature of the damage, specific types of cables, connectors, or tools may be needed to ensure a successful repair.

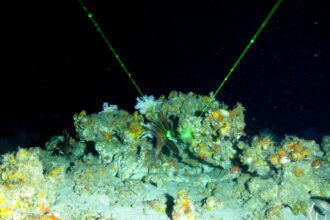

Establishing relationships with reliable suppliers can streamline this process and help teams access high-quality materials in a timely manner. In addition to physical materials, teams must also consider any specialized equipment required for the repair. This may include machinery for digging or lifting, testing devices for assessing cable integrity, or safety gear for personnel.

Proper procurement not only ensures that repairs can be conducted efficiently but also minimizes delays caused by equipment shortages or malfunctions. By planning ahead and securing all necessary resources in advance, teams can maintain momentum throughout the repair process.

Coordinating with Utility Companies and Local Authorities

| Stage | Estimated Duration | Key Activities | Responsible Team | Notes |

|---|---|---|---|---|

| Damage Assessment | 4-6 hours | Site inspection, damage identification, initial report | Field Engineers | Rapid response critical to minimize downtime |

| Resource Mobilization | 12-24 hours | Gathering repair materials, equipment, and personnel | Logistics Team | Depends on location accessibility |

| Transportation to Site | 6-18 hours | Transporting crew and materials to repair location | Logistics & Transport | May vary due to weather or terrain |

| Repair Execution | 8-24 hours | Cutting, splicing, testing, and securing cable | Technical Repair Team | Complex repairs may extend duration |

| Testing & Verification | 2-4 hours | Signal testing, quality assurance, documentation | Quality Control | Ensures repair integrity before service restoration |

| Site Clearance & Reporting | 1-2 hours | Cleanup, equipment retrieval, final report submission | Field Engineers & Logistics | Final step before project closure |

Coordinating with utility companies and local authorities is an essential aspect of cable repair that cannot be overlooked. These entities often play a significant role in facilitating repairs by providing access to infrastructure or resources that may be necessary for completing the job. Effective communication with these stakeholders helps ensure that all parties are on the same page regarding timelines, responsibilities, and safety protocols.

Moreover, utility companies may have specific requirements or procedures that must be followed during repairs to maintain service continuity for their customers. By collaborating closely with these organizations, repair teams can minimize disruptions and ensure that services are restored as quickly as possible. This coordination also extends to local authorities who may need to manage traffic or public safety during repairs.

By working together, all parties can contribute to a more efficient repair process that benefits both service providers and affected communities.

Mobilizing and Deploying Repair Crews

Mobilizing and deploying repair crews is a critical phase in executing a successful cable repair project. Once all preparations are complete, it is time to assemble skilled personnel who will carry out the actual work. This involves not only selecting qualified technicians but also ensuring they are equipped with the necessary tools and materials for their tasks.

Effective mobilization requires careful planning to ensure that crews arrive on-site promptly and are ready to begin work without unnecessary delays. Deployment of crews also necessitates clear communication regarding roles and responsibilities. Each team member should understand their specific tasks as well as how they fit into the larger repair effort.

Additionally, having a designated project manager on-site can facilitate coordination among different teams and ensure that any issues are addressed promptly as they arise.

Implementing Safety Protocols and Procedures

Safety is paramount during any cable repair operation, making it essential to implement robust safety protocols and procedures before work begins. This includes conducting thorough safety briefings for all crew members to ensure they understand potential hazards associated with their tasks. Personal protective equipment (PPE) must be provided and worn at all times to minimize risks related to electrical exposure or physical injuries.

In addition to individual safety measures, teams should also establish emergency response plans in case of accidents or unforeseen incidents during repairs. These plans should outline clear procedures for reporting injuries or hazards, as well as steps for evacuating personnel if necessary.

Communicating with Stakeholders and Affected Parties

Effective communication with stakeholders and affected parties is vital throughout the cable repair process. Keeping everyone informed about progress, potential delays, or changes in service helps manage expectations and fosters goodwill within the community. Regular updates can be disseminated through various channels such as social media, local news outlets, or direct notifications to residents and businesses in the area.

Moreover, establishing a point of contact for inquiries or concerns allows stakeholders to voice their questions or feedback directly to project managers. This open line of communication not only enhances transparency but also builds trust between repair teams and the community they serve. By actively engaging with stakeholders throughout the repair process, teams can mitigate frustrations and create a more positive experience for everyone involved.

Monitoring Progress and Adjusting the Timeline as Needed

Monitoring progress during cable repairs is essential for ensuring that projects stay on track and within budget. Regular check-ins with crews allow project managers to assess whether work is proceeding according to schedule or if adjustments need to be made due to unforeseen circumstances. This proactive approach enables teams to identify potential bottlenecks early on and implement solutions before they escalate into larger issues.

Adjusting timelines as needed is an inevitable part of any repair project; however, it should be done thoughtfully and transparently. If delays occur due to weather conditions or unexpected complications, communicating these changes promptly to stakeholders is crucial for maintaining trust. By being transparent about challenges faced during repairs while also providing updated timelines, teams can foster understanding among affected parties.

Completing the Repair and Conducting Quality Checks

Upon completion of repairs, conducting thorough quality checks is imperative before restoring service to customers. This final phase involves testing cables for functionality and ensuring that all connections are secure and compliant with industry standards. Quality assurance measures help identify any lingering issues that may need addressing before full service restoration occurs.

Once quality checks are completed successfully, teams can proceed with restoring service to affected areas. Communicating this milestone to stakeholders is important as it marks a significant achievement in the repair process. Celebrating successful completion not only reinforces team morale but also demonstrates commitment to customer satisfaction by ensuring reliable service delivery.

Documenting and Reporting on the Cable Repair Process

Finally, documenting and reporting on the cable repair process serves multiple purposes beyond mere record-keeping. Comprehensive documentation provides valuable insights into what worked well during repairs as well as areas for improvement in future projects. Detailed reports can also serve as references for regulatory compliance or audits conducted by utility companies or local authorities.

Moreover, sharing lessons learned from each project contributes to ongoing training efforts within organizations involved in cable repairs. By analyzing successes and challenges faced during repairs, teams can refine their processes over time, ultimately leading to more efficient operations in future endeavors. In this way, documentation becomes an integral part of continuous improvement efforts within the industry.

In conclusion, navigating through each stage of cable repair requires careful planning, coordination, and communication among various stakeholders involved in the process. From understanding timelines to documenting outcomes post-repair, each phase plays a vital role in ensuring successful project execution while prioritizing safety and stakeholder engagement throughout every step taken along this journey.

For those interested in understanding the complexities of cable repair timeline logistics, a related article can be found on In The War Room. This resource provides valuable insights into the planning and execution of cable repairs, ensuring that timelines are adhered to and disruptions are minimized. You can read more about it in their article [here](https://www.inthewarroom.com/).

FAQs

What factors influence the timeline for cable repair?

The timeline for cable repair depends on factors such as the type and extent of the damage, location of the cable, accessibility, weather conditions, availability of repair materials, and the complexity of the repair process.

How long does a typical cable repair take?

A typical cable repair can take anywhere from a few hours to several days. Minor repairs may be completed within a day, while major repairs involving extensive damage or difficult access can take longer.

What logistical steps are involved in cable repair?

Logistical steps include damage assessment, securing necessary permits, mobilizing repair crews and equipment, coordinating with utility companies, transporting materials to the site, performing the repair, and testing the cable before restoring service.

How does location affect cable repair logistics?

Remote or hard-to-reach locations can increase repair time due to transportation challenges and limited access to resources. Urban areas may require coordination with local authorities and traffic management, which can also impact timelines.

What role does weather play in cable repair timelines?

Adverse weather conditions such as heavy rain, storms, or extreme temperatures can delay repair work by making the site unsafe or inaccessible, and by affecting the performance of repair equipment.

Are there different timelines for underground versus aerial cable repairs?

Yes, underground cable repairs often take longer due to the need for excavation and soil stabilization, whereas aerial cable repairs can be quicker but may require specialized equipment like bucket trucks and safety measures for working at heights.

How is communication managed during cable repair projects?

Effective communication involves coordinating between repair teams, utility companies, local authorities, and affected customers. Updates on repair progress and estimated restoration times are typically provided to stakeholders to manage expectations.

Can cable repair timelines be expedited?

Timelines can sometimes be shortened by pre-positioning repair materials, having trained rapid response teams, using advanced diagnostic tools, and streamlining permit and coordination processes.

What safety considerations impact cable repair logistics?

Safety protocols for working near live cables, traffic control, use of personal protective equipment, and adherence to regulatory standards are critical and can influence the pace and scheduling of repair activities.

How are cable repair priorities determined?

Priorities are usually based on the impact of the outage, such as critical infrastructure needs, number of customers affected, and potential safety hazards, which guide the allocation of resources and scheduling of repairs.